How Wineries Use Centrifuges for Grape Processing

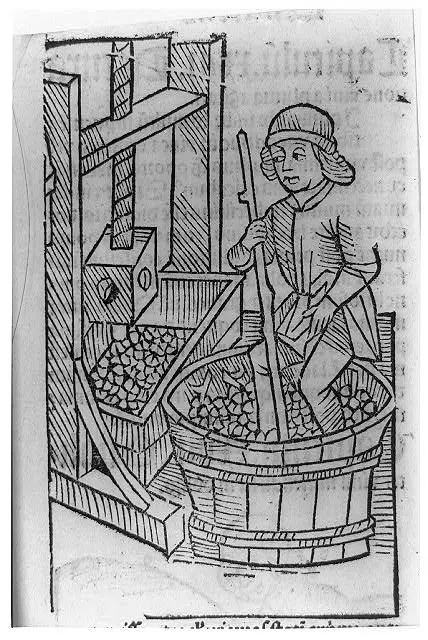

You obviously don’t need a centrifuge for winemaking. For nearly 10,000 years humans have been stomping grapes, mashing up fruit and honey, or spitting starchy root pulp into jars, then letting it ferment. Wine happens.

That said, most commercial-scale winemakers use centrifuges. Why? Because centrifugation is a quick and effective method for separating liquids and insoluble matter without the risk of degrading your wine. This protects flavors while improving quality and consistency. And it does this while increasing yields and saving an enormous amount of time. All of that adds up to a healthier bottom-line (and a better glass of vino).

Centrifuges are Indispensable for Modern Winemaking

In larger scale winemaking, it isn’t uncommon to use a centrifuge (like the CentraSep DW-Series vertical disk stack centrifuge) at almost every stage of grape processing and winemaking.

After grape clusters are picked, de-stemmed, and pressed/crushed, the resulting juice makes its first trip through the centrifuge (at least in the case of white wines). This clarifies the juice while eliminating potentially weeks of racking and repeated exposure to oxygen (plus saving the juice otherwise lost during each racking).

From there, the wine goes into fermentation barrels or tanks. Once fermentation is complete, it’s back to the centrifuges to remove the remaining yeast bodies or other particulate. In some cases, winemakers use their centrifuge to prematurely halt fermentation by removing still active yeast, resulting in sweet wine with less guesswork. If further aging is required, then there may be another centrifuging step to catch charcoal or wood particles picked up during barrel aging. Finally, winemakers will centrifuge their wine at least once more for a final clarification prior to moving it to the bottling tanks.

Use a Centrifuge to Get More of a Better Product

“Of course, you can still make wine without a centrifuge,” notes Chris Clausen, Craft Beverage Industry Manager at Trucent. “But for any modern larger scale facility, your yield increase and time savings are just huge once you introduce centrifuge clarification. And you also see a big bump in product quality and consistency.”

In part, this is because using a centrifuge can eliminate the need for flocculants and other additives. Flocculation is chemistry. It brings with it all the complexities of chemistry, as well as the time it takes for chemical reactions to take place and sedimentation to occur. Centrifugation is a mechanical process. With a good programmable centrifuge, winemakers are able to directly harness the clarification in real-time, controlling how quickly it occurs, what materials are separated, and how completely every last bit of wine is wrung out of the particulate cake. Between recovered wine, reduced inputs, and saved time, a high-speed centrifuge can quickly prove itself to be the best financial option.

Trucent’s DW Series are of wine centrifuges self-cleaning, and come in 10 sizes (making it easier to find a model that fits both facility, production volume, and budget). These centrifuges use hydraulic seals or mechanically sealed hermetic bowls to absolutely minimize oxygen pick, protecting the unique character of your wine. (The hermetic seal guarantees the lowest dissolved oxygen pickup on the market, always less than 10 ppb, usually near zero ppb.)