In-line, Auto-Purging, High Intensity Magnetic Separation and Metal Particle Capture

Fines, metals, and mineral contaminants can cost you a fortune when they’re not reliably separated from process fluids. Plants with seemingly sufficient magnetic separators and particle capture systems often run smoothly for weeks. Then, abruptly find themselves forced to scrap tens of thousands of dollars in parts and materials.

In one case, we visited an automotive powertrain manufacturer who was struggling with cost overruns and missed production goals because of metal particles in their honing oil, even with magnetic separators designed to catch iron and other ferrous materials and fines. Nonetheless, impurities in their honing oil still regularly spiked orders of magnitude above their 30 parts-per-million (PPM) upper control limit (UCL). This didn’t just result in downtime and ballooning material costs (i.e., dumping honing oil, cleaning the magnetic separators, recharging the fluids, etc.), they were also scrapping multiple engine blocks each week.

The problem was that magnetic separator. It was an older style of bar magnet separator, one with a weaker magnetic field, only able to separate fines around 30 µm. This might have been sufficient in an ideal world. But no filter runs in an ideal world. In the real world, as a separator runs, ferrous particles accumulate on the magnet. This naturally diminishes the magnetic field and degrades the separator’s capacity to catch more iron and other ferrous material. In this facility, the magnet separator had to be manually cleaned. However, magnet cleanings rarely happened, because the issues with the metal fines and rejected parts kept everyone so busy. As a result, their normal operating conditions were just barely below the UCL, making a spike in metal fines inevitable.

The problem was that magnetic separator. It was an older style of bar magnet separator, one with a weaker magnetic field, only able to separate fines around 30 µm. This might have been sufficient in an ideal world. But no filter runs in an ideal world. In the real world, as a separator runs, ferrous particles accumulate on the magnet. This naturally diminishes the magnetic field and degrades the separator’s capacity to catch more iron and other ferrous material. In this facility, the magnet separator had to be manually cleaned. However, magnet cleanings rarely happened, because the issues with the metal fines and rejected parts kept everyone so busy. As a result, their normal operating conditions were just barely below the UCL, making a spike in metal fines inevitable.

High-Intensity Magnetic Separators for Industrial Applications

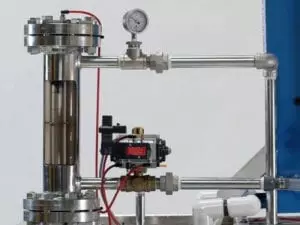

Trucent helped them pull their old magnet separators offline and temporarily replace them with something more suitable: a modern in-line, auto-purging, self-cleaning high intensity magnetic separator. This separator can capture particles as small as a 1 µm. It has a footprint four times smaller than conventional gravity-fed fluid purification and fines-capture systems. And because it was both self-cleaning and media-free, this high intensity magnetic separator could run 24/7 with little or no operator interaction, freeing up worker time as well as plant floor space.

During a six-month test period with the new magnetic separator, metal particle contamination in the honing oil never exceeded the UCL. With a Trucent magnetic separator, in two-thirds of the honing oil, the particulate level was below 50% of the UCL. Frequently, the particulate level was as low as 90% below UCL, making it much easier to stay ahead of any issues in oil purity. They didn’t scrap a single engine block (a savings of $27,000) and enjoyed a net increase of 3.3 jobs per hour at end of line. After three years with this solution, the system continued operating with remarkable consistency and reliability: their maintenance costs had dropped to zero, saving hundreds of work hours each year.

Process-Oriented Magnetic Separation Applications Design

Process-Oriented Magnetic Separation Applications Design

At Trucent we’re dedicated to a process-oriented approach. This has meant building teams with a broad range of specialties: non-disposable media filtration, centrifuges, high intensity magnetic separation, non-magnetic/non-ferrous metals processing, the fundamental physics and chemistry of fluid separation, and the specific challenges faced in manufacturing and fabrication.

That team works with you to find the right intervention, use the right technology, and match it to the right application.

But this isn’t just about equipment. We can install a Trucent team in your plant to run and manage all your fluids and separation technology daily. Your in-house Trucent team will do more than just handle fluid purchases, monitor those fluids, and maintain them at appropriate levels and concentrations. They’ll pinpoint contaminants at their source and find ways to separate these contaminants from your flow as early as possible. When those fluids are spent, they’ll dispose of them with minimal negative impact to your business and our world.

No one else offers this comprehensive level of fluid management service—because no one else starts every solution with a conversation. Contact us to begin that conversation. A member of our team will visit your facility, at no obligation or cost, to walk your entire process, sample fluids, and develop a deep understanding of what you do. We’ll take your fluids back to our labs for analysis, then design and pilot a metal and mineral separation/purification system that will meet your spec. As needed, those solutions will then be trialed on site for as long as it takes to be sure that it will reliably get the job done.

No one else offers this comprehensive level of fluid management service—because no one else starts every solution with a conversation. Contact us to begin that conversation. A member of our team will visit your facility, at no obligation or cost, to walk your entire process, sample fluids, and develop a deep understanding of what you do. We’ll take your fluids back to our labs for analysis, then design and pilot a metal and mineral separation/purification system that will meet your spec. As needed, those solutions will then be trialed on site for as long as it takes to be sure that it will reliably get the job done.

Comprehensive Magnetic Separation Equipment, Solutions & Services

Trucent provides comprehensive solutions that effectively separate magnetic particles and other contaminants, processing your fluids for longer life and better performance. We can help you maintain your existing high intensity magnetic separator or design an entirely new separation system. We can install one piece of equipment or an entire team to manage all your fluids filtration technology daily. The goals remain the same: Cleaner fluid, longer tool life, higher quality parts, and lower costs.

Contact a Magnetic Separator Expert

Engine Manufacturer Reduces Honing Oil Costs by 70%

Since implementing the solution, the engine manufacturer reduced fluid-related costs on this honing operation by 70% and realized an investment payback in less than three months. The plant is more productive after eliminating the introduction of contaminants to their process.

Related Solutions, Services & Products

Solutions

Services

Client-Site Services

Committed to Service

With the largest fleet of separation technology, advanced engineering, and chemistry capability across a wide array of industries and experienced operations personnel throughout North America, you can count on us when you need us most.

- 9 Service Locations Across North America

- The Largest Fleet of Separation Technology

- Over 150 of Fluid Experience