Good oil, fluid, and lubricant is the lifeblood of your process. It leads to cleaner processes, cleaner machines, cleaner tools, and the right flow and pressure delivered at each operation. But oil invariably collects contaminants. This drives unpredictable tool wear, poor part quality, inconsistent results, and piles of rejects.

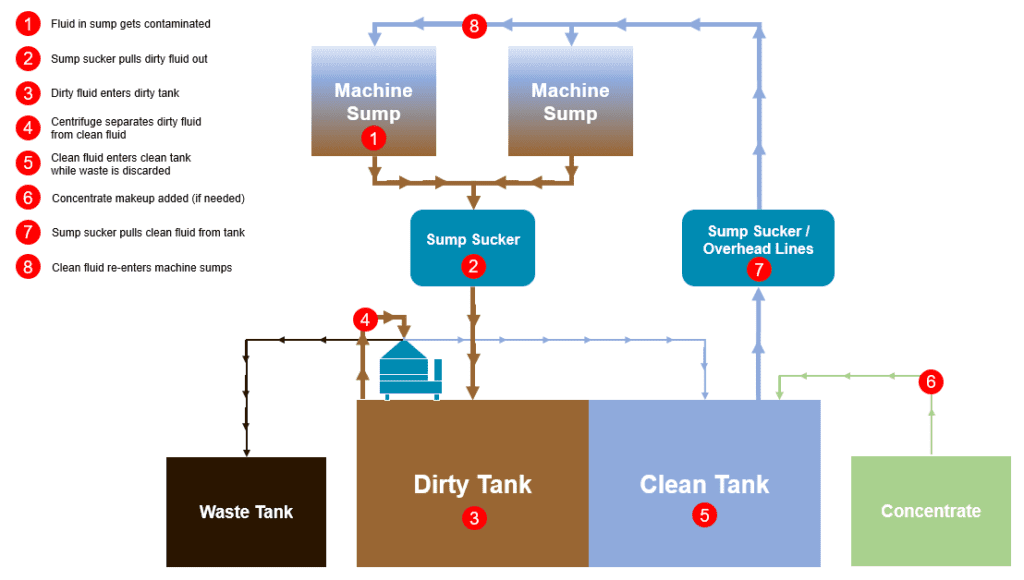

Trucent’s batch reclamation system removes dirty oil and lubricant from your manufacturing process and shunts it into a “dirty tank.” From there, we leverage a vast array of separation technologies to clean that oil up. Once the fluid is purified to spec, it is then returned to the process. Batch reclamation reduces the amount of metalworking lubricants required for applications and eliminates the need for dumping and recharging your sumps. As a result of consistently using clean oil and coolant, our customers see an overall decrease in tool wear and downtime, with an improvement in part quality and other outcomes.

Batch reclamation is a surefire way to reduce waste, save money, and improve product quality while increasing tool life and enhancing operator environment. Trucent’s batch reclamation systems can be custom-fit to your plant or executed with our mobile oil purification truck.

A Process-Oriented Approach to Fluid Reclamation, Recycling, and Disposal

We’re dedicated to a process-oriented approach to oil recycling and waste fluid management. This has meant spending decades investing in a team composed of more than equipment experts and engineers. Our team brings together decades of experience with non-disposable media filtration, centrifugal separators, vacuum dehydrators, and other equipment—as well as experts in the fundamentals of oil/water/fluid separation, and the intricacies of your industry and processes. We work with you to find the right intervention, use the right technology, and match it to the right application.

Our operations team can maintain the entire solution on an ongoing basis so you can completely outsource your batch reclamation and other filtration technology to us. With the largest fleet of separation assets, including batch reclamation systems, in North America, we are ready to take care of your needs.

No one else offers this level of comprehensive oil reclamation and wastewater management service.

Every solution begins with a conversation. Contact us today to begin that conversation, or schedule a no-obligation on-site visit. A Trucent engineer will come to your site and walk your entire line, sampling oil at every important stage. After off-site lab analysis, we’ll be able to recommend the best solution.

Comprehensive Recycling, Reclamation, and Filtration Solutions & Services

Trucent provides comprehensive maintenance, oil reclamation, and disposal solutions. We can help you maintain your existing equipment—or design an entirely new reclamation solution. We can install one piece of equipment or an entire team to manage all your filtration equipment daily. The goals remain the same: Cleaner fluid, longer tool life, higher quality parts, and a better workplace with reduced waste, reduced environmental impacts, and lower costs.

Contact a Batch Reclamation Expert

Engine Manufacturer Reduces Honing Oil Costs by 70%

Since implementing the solution, the engine manufacturer reduced fluid-related costs on this honing operation by 70% and realized an investment payback in less than three months. The plant is more productive after eliminating the introduction of contaminants to their process.

Related Solutions, Services & Products

Solutions

Services

Client-Site Services

Committed to Service

With the largest fleet of separation technology, advanced engineering, and chemistry capability across a wide array of industries and experienced operations personnel throughout North America, you can count on us when you need us most.

- 9 Service Locations Across North America

- The Largest Fleet of Separation Technology

- Over 150 of Fluid Experience